Producing solar cells with zero-emissions electricity will provide new manufacturing opportunities for local industries.

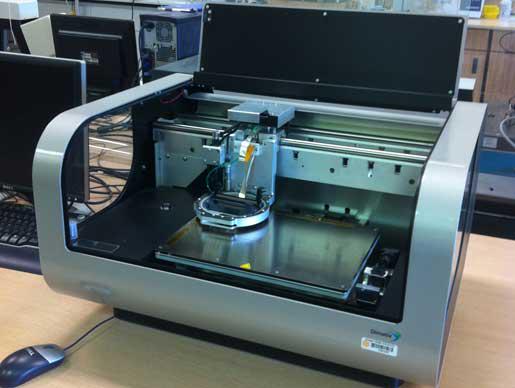

Australian solar cells researchers and industry have partnered to develop innovative ways of generating zero-emissions electricity using a printing machine to produce solar cells.

The $7.2 million project will see the development of a possible alternative solar cell technology compared with more conventional photovoltaic systems. It is expected that the products will provide Australia industries the opportunity to commercialise and produce the cells competitively.

The Federal Government will contribute a $1.7 million grant through the Australian Solar Institute with the Victorian Government providing funding of equal amount.

Launched in Melbourne yesterday, Minister for Resources and Energy, Martin Ferguson AM MP said the project was aimed at developing efficient solar cells using organic materials and conventional printing methods.

The project will see researchers at the University of Melbourne, the CSIRO Future Manufacturing Flagship, and Monash University collaborate with industry partners BlueScope Steel, Innovia Films and Robert Bosch to take commercialese their printing machine innovation.

“This collaboration between researchers and industry partners will help commercialise the technology across a variety of potential applications, including for example as a coating for other material such as roofing steel,” Mr Ferguson said.

“Using low-cost and readily available organic materials to print solar cells through established industrial processes where we already have a competitive advantage offers the potential for solar cells to be manufactured at low-cost in Australia.

“Australia is a leader in solar energy research and projects such as this will help Australia remain at the forefront of this rapidly growing industry.” He said.

The funding is part of the Government’s Clean Energy Future package which is aimed at building on existing support for clean and renewable energy projects.

By Annie Dang