Stanford scientist Xiaolin Zheng, head of the Zheng Research Group at Stanford University claims that she and her team has created thin, flexible solar cells, or solar stickers, that are made from standard materials which can be applied to almost any kind of surface.

If this is true, solar stickers would revolutionize the way solar cells are made. Conventional thin-film solar cells are made with stiff glass substrates, thereby limiting their potential applications. Although there are more flexible options, they require special materials and a delicate production process.

Zheng: Creating the Solar Sticker

Zheng is a nano-scientist as well as a National Geographic Emerging Explorer. From her younger days, she sought to provide solutions to the problems related to solar power. She observed that his parent’s effort to convert to solar power was made more difficult because of the limited roof space where solar panels are traditionally installed.

This Stanford scientist remembers the off-hand comment of his father that it would be easier if they can only hang theirsolar panels out their windows. This will give them easier access, easier piping and reduced competition for roof space.

The prospect of creating solar stickers through the method developed by this Stanford scientist is great because there are tons of natural resources that can be used for this purpose. Concerns about the raw materials and their sources are things that confront PV manufacturers as they develop modern technologies that can cope with our ever-growing demand for consumption.

Solar power is the best alternative in coping with this constantly increasing energy demand since it is widely and easily accessible, and will not run out of supply.

Solar Sticker Development Process

The process of making the peel-and-stick solar stickers is quite simple. The researchers at Stanford University started the process by applying a 300-nanometer layer of nickel onto a stiff silicon/silicon dioxide wafer.

By applying standard fabrication techniques, they then deposited thin-film solar cells onto the nickel. Afterwards, they applied a protective polymer over the solar cells. They followed it up with a layer of thermal release tape which they applied over the cells.

The sandwiched material is then submerged in water at room temperature. One edge of the tape is peeled off, letting the water seep in between the wafer and the nickel layer. As soon as the nickel is completely separated from the wafer, the researchers have a bare wafer, with the tape still clinging onto it.

This tape, together with its contents is then heated to about 90 degrees Centigrade for a few seconds. Adhesive is applied to the non-tape side, and the whole item is then applied to a selected surface.

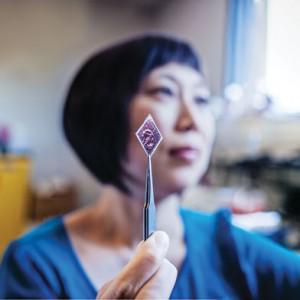

When the tape is peeled off, all that will be left are the polymer-coated cells, which adhere to the surface just like a decal: a solar sticker.

These solar stickers definitely have more potential than conventional solar cells. They will reduce the cost of production of solar cells because they will do away with the glass/silicone substrate which takes up most of the structure of conventional solar panels.